What's a Substation Technician?

Journeyman Substation Technicians build, maintain, operate, and repair electrical power substations, switchyards, and associated systems. Every project is complex, challenging, rewarding, and requires careful management of a skilled team of professional power workers—the construction, operation, and maintenance of substations and switchyards involves special skills and advanced technologies. In addition, workmanship must be of the highest quality because the station and switchyard will operate unattended for 30 years or longer when the project is done.

As an extension of the outside line series of electrical crafts, Journeyman Substation Technicians work alongside Mechanical, Civil, Structural, and Electrical engineers, Journeymen Lineman, Journeymen Wiremen,apprentices, operators, and laborers from these and other trade classifications. Each specialized electrical worker brings unique skills and abilities to assist the Journeymen Substation Technician in their work to complete these projects as a ‘jack of many trades’ and a Master of one, the Electrical Substation & Switchyard.

Assembly and erection of substations and switchyards

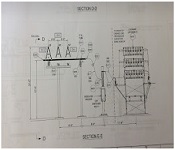

- Read blueprints to determine plans for substations and switchyards

- Coordinate excavation for placement of ground grids

- Layout trenches for conduit for the substation and lay, secure and reinforce conduit

- Install and terminate the control cable

- Prepare concrete footings for the erection of substation structures

- Install transformers, OCBs, OCRs, capacitor banks, and other related equipment

Safety risk management

- Provide practical safety job planning methods

- Identify, eliminate, and mitigate hazards

- Review and maintain OSHA, employer, utility, and jurisdictional safety standards

- Inspect and maintain tools and personal protective equipment

- Understand and follow written procedures and safety manuals

- Maintain readiness and state of response preparedness

The role of a substation in an electrical system

- Substations are critical meeting points between the three subsystems of the electrical grid:

- Electric Generation

- Electric Transmission

- Electric Distribution

- The main function of a substation is to step voltage up from a generating station so it can be transmitted long distances

- Another function is to step down transmission voltages to distribution voltages to be used by customers

Planning and initiating jobs

- Study blueprints and specifications

- Organize material, tools, equipment, and labor

- Load and unload equipment at the job site

- Establish and maintain timetables for work

- Project management duties

- Conduct pre-job meetings

Classroom and self-paced studies

- Read, study, and understand textbooks at a disciplined self-pace to meet timelines

- Successfully pass computer-based online content and quizzes

- Attend class sessions and participate in academic lectures and hands-on application of knowledge

- Successfully pass proctored classroom tests and exams, including hands-on performance assessment tasks

Use tools and test equipment

- Conduct concrete slump, air content, and strength tests

- Test insulation resistance

- Continuity testing

- Measure resistivity

Install below-grade foundations

- Dig and frame tren-ways

- Install conduit

- Pull communication cables

- Lay cables in raceways

- Install ground rods and grid

- Make ground connections

- Install rebar

- Install concrete & grout

- Install, splice, and terminate power cables

Wire cabinets and relay panels

- Inspect equipment

- Install steel support panels

- Positions relay panels

- Label panels per drawings

- Attach grounds and connections

- Make ohmmeter checks

Install capacitor banks

- Inspect equipment and assemble per instructions

- Record date from nameplates

- Position capacitors on structures per engineering plans

- Install fuses and switches

- Verify buswork and circuit layout

- Attach station grounding equipment

- Label capacitors, disconnects, and controls

Install power circuit breakers

- Review written safety plans

- Handle SF6 gas with care

- Verify engineering plans

- Pour concrete pads

- Assemble steel support structures

- Anchor units to poured concrete pads

- Torque all components per manufactured specs

- Install the conduit and auxiliary components

Install power transformers

- Inspect all bushings and components

- Pour structural concrete pads

- Build oil containment systems

- Assemble large units in pieces

- Position the transformer in the proper location on-site

- Attach the unit to the slab

- Verify phasing agrees with nameplate and bushings

- Verify transformer polarity

- Attach radiators, conservator tanks, fans, pumps, and oil

Install disconnect switches

- Inspect all components for shipping damage

- Assemble using exact hardware and material

- Install insulators and rotating mechanical shafts

- Align operating mechanisms and rotating levers

- Lift, mount, and install assemblies

- Check and verify alignment

- Install accessories and jumper assemblies

Install distribution transformers for station power

- Identify nameplate ratings

- Make primary connections

- Connect internal winding configurations

- Make secondary connections

- Test and operate switches to energize units

- Verify voltages, currents, and impedances

- Troubleshoot and repair transformer problems